The number of milled parts being produced is constantly increasing. In order to manufacture a milled part (online),

factors such as design, functionality, batch size and the appropriate material to be used must be determined.

What other aspects need to be taken into account in the design phase, to facilitate production?

Or what options are there for determining the right material for the production of milled parts?

Before a milled part is designed and manufactured, it should be planned. This involves central questions such as

"Why and for what is the milled part needed later?"

"Is the requirement available?", "How large must the quantity to be ordered be?" and "Is internal consultation with designers or the supervisor necessary?"

All these questions should be answered and clarified in advance.

Only then can a smooth process be guaranteed.

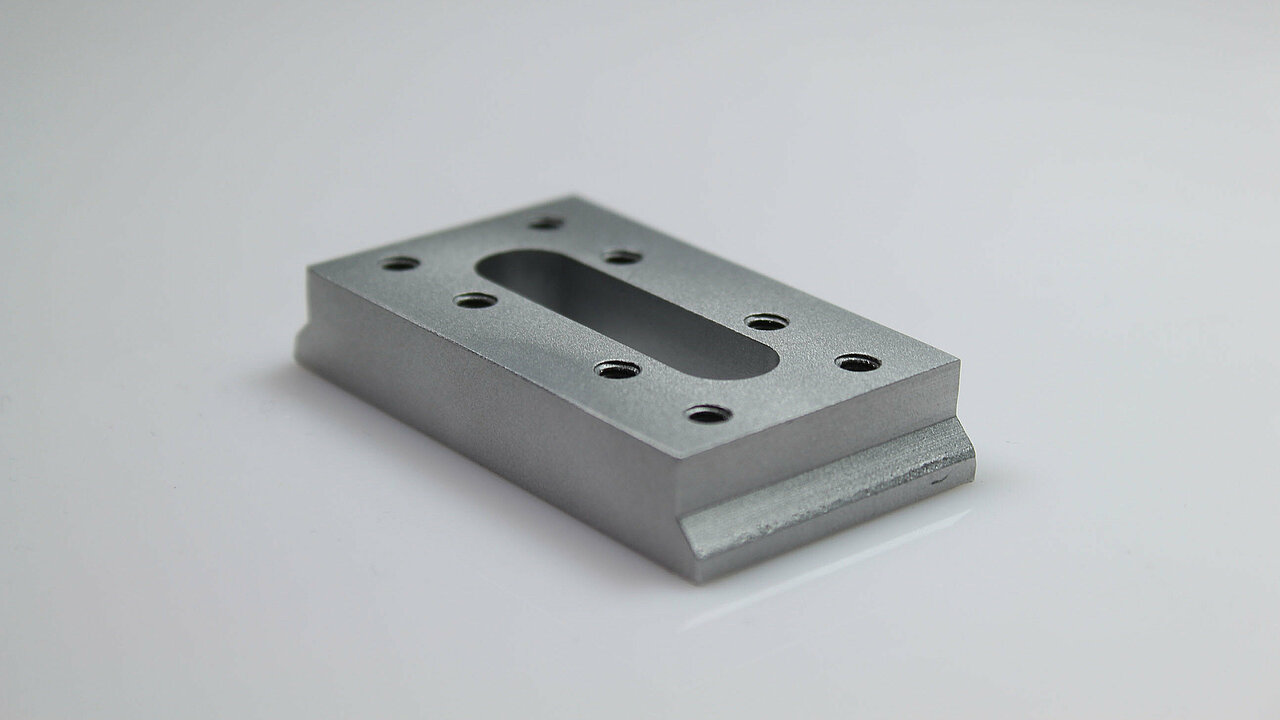

The steps to the milled component begin with the design of components. This is a process-specific design of construction components. Special tools or special devices can be used to simplify the design of milled parts and the subsequent milling process. However, these may be expensive for the manufacturer and for the person who ordered the milled part, as both have to bear the increased costs. When thinking about the design of a component, the aims of this process can be, for example, the use of a cheap and readily available material or a short programming and production time. Other objectives include minimising sources of error in the final component or avoiding queries by producing a drawing that is easy to understand.

Ultimately, a design also aims to avoid the use of special tools and complex post-processing (e.g. hardening). General design rules can help to ensure that only a few special tools or procedures are used in the design. At the beginning, the complexity of the component should therefore be minimised without disregarding the intended functionality. Although free-form surfaces and complex machining processes are possible, they involve more programming effort. Furthermore, undercuts are difficult to achieve due to the rotation axis of the tool, which is why they should only be used rarely. Very thin wall thicknesses should also be avoided wherever possible. Thin wall thicknesses vibrate quickly so that the achievable tolerances are reduced and there is insufficient rigidity during the milling process. With soft materials, for example, it should be noted that greater wall thicknesses are advantageous. This is particularly important for later use.

There are also various options for saving costs in design and milling.

On the one hand, it is possible to reduce costs in planning and design,

by creating a specification that meets the requirements and reducing unnecessary, superfluous or excessive quality requirements.

In most cases, this also directly reduces the costs for production and

the subsequent quality controls. To this end, the specifications that come from the development department should be precisely implemented/observed in the design department, then checked and, if necessary, corrected and adapted. Companies can ensure quality through the use of technical or personnel measures.

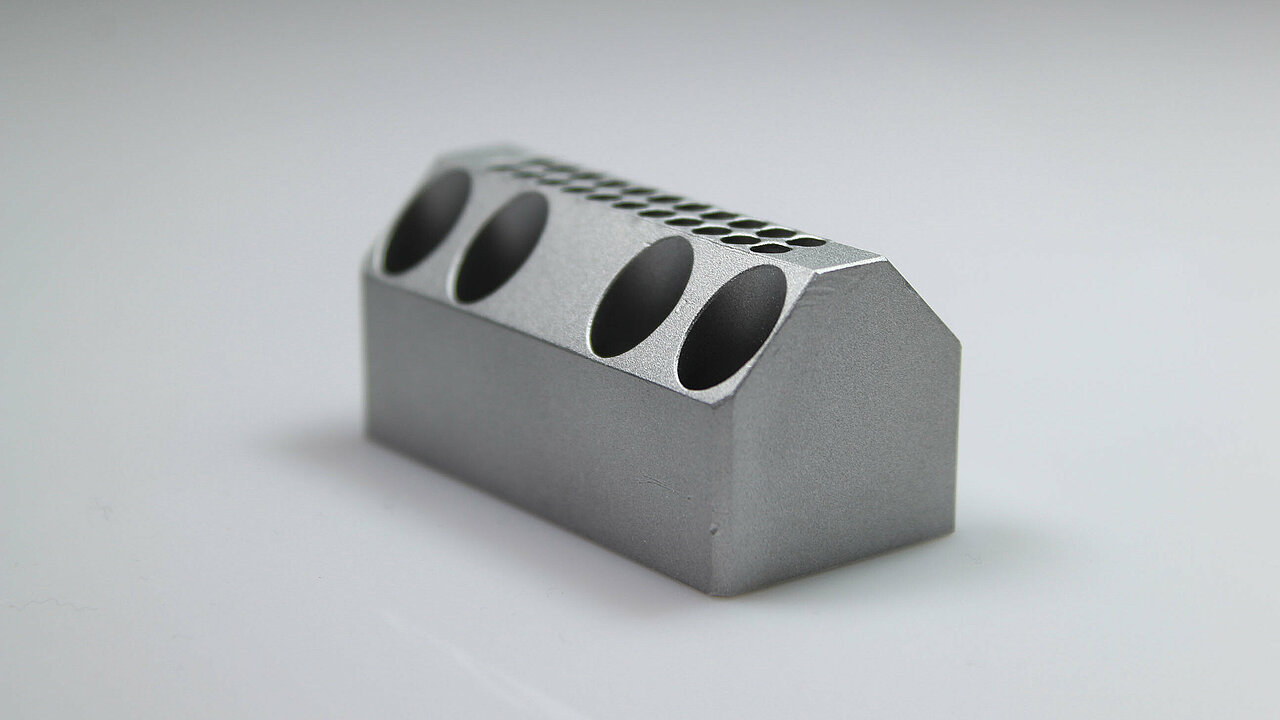

In order to mill a component, it is first important to know which materials are best suited to the requirements of the component to be manufactured and what requirements the materials have. In principle, all machinable materials can be selected for milling. Machinable materials include steel, aluminium, stainless steel, brass, copper and many plastics. Cutting speeds of 200 - 3000 m/min are used to mill plastics. However, as this material must be cooled during milling, a different cooling lubricant, such as water or oil, is used depending on the hardness and plastic behaviour. For metals, the cutting speed differs depending on the toughness or brittleness of the material.

Due to the wide range of metals and the different requirements and properties, the cutting speeds can be very broadly defined here.

For example, cutting speeds of 15-500 m/min are used in workshops or training centres. In series production or for very milling-intensive workpieces, however, a cutting speed of up to 10,000 m/min can be used. Depending on the type of material selected, different cooling lubricants must be used for cooling during machining. It is possible to choose between water, oils and emulsions. The next step is to choose the right material for the milled part, taking various aspects into account.

Firstly, the technological, chemical and mechanical properties of the various materials should be analysed and taken into account when selecting the material. The important question here is

"What properties does the component to be manufactured need and what properties do the materials have?" It should also be noted

whether the component requires a certain temperature resistance and select the material based on this. This is because every material is resistant to different temperatures. Capabilities such as a certain lightness, corrosion resistance or the task of an electrical or thermal conductor for the use of the component are important aspects for the right choice of material.

Various factors should also be taken into account during the manufacturing process, i.e. milling, in order to avoid reworking due to errors/problems. One of the most important factors is the cutting speed mentioned above. It depends on the material to be machined and the milling intensity of the workpiece. In addition to the cutting speed, the feed movement must also be taken into account. This determines the surface quality and the cutting load that can be achieved. Other important variables are the chip thickness, the cutting width, the cutting depth and the pressure angle. The pressure angle is the angle between the entry and exit. The metal removal rate is a variable that must be taken into account when milling. It indicates the volume removed from the workpiece per minute. The aim is of course a high metal removal rate,

but without overloading the tools, the milling machine or the milled part. With milling, it is possible to produce not only very complex workpieces with a variety of geometric contours, but also surfaces and rotationally symmetrical parts.

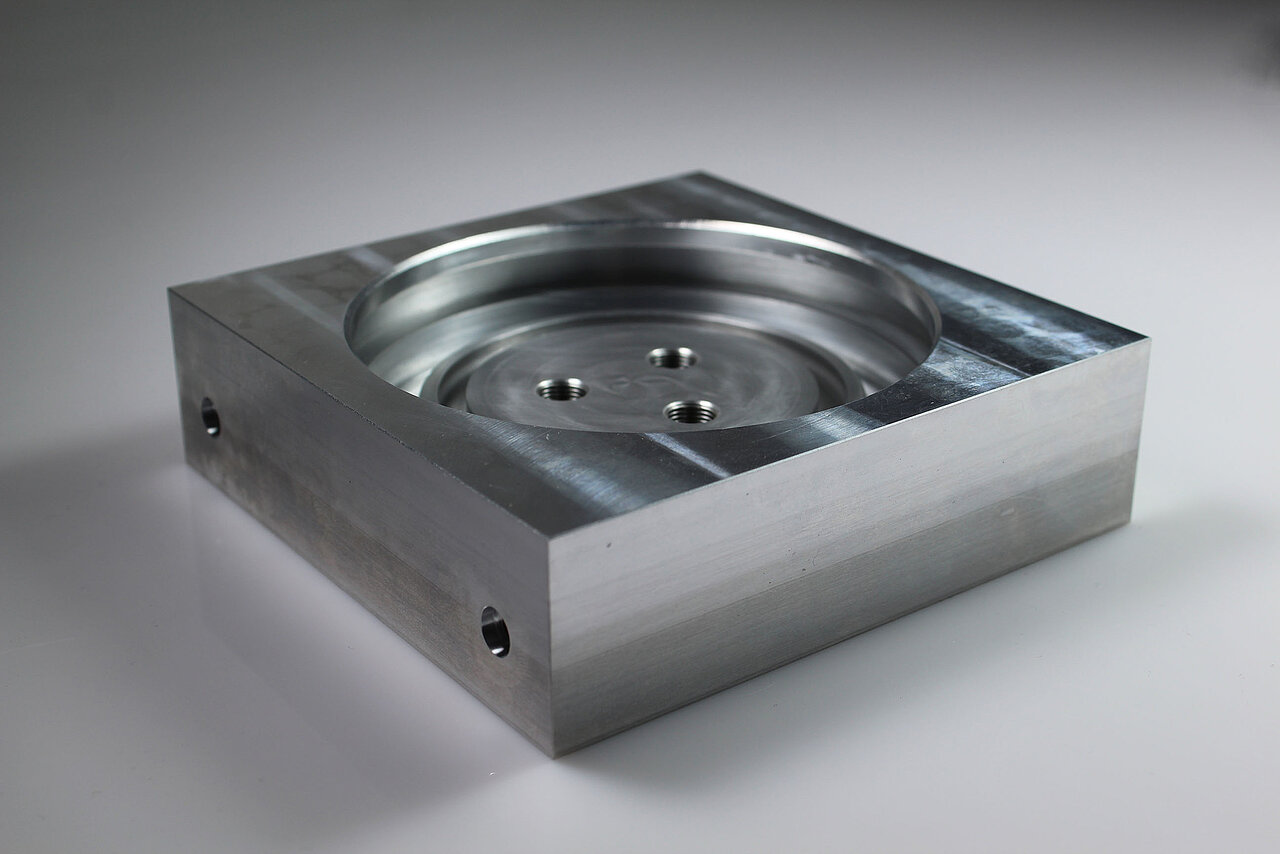

Now that the milled part has been manufactured a quality check should be carried out. This is an important step to determine whether the milled part meets the previously defined requirements and the production drawing.

Tip: If the component has been sent, the first thing to check is the packaging and whether the packaging of the component is in perfect condition? Transport damage must always be documented so that rectification can be arranged as quickly as possible. After unpacking, it is important to check the appearance of the component and check whether it is clean and deburred. A rough external inspection should also be carried out so that you can check that all holes are present and threads are in the right places.

Checking the material and surface quality are also important steps that should be checked briefly. Finally, all dimensions should be checked against the production drawing and tolerances. This begins, for example, with checking a caliper gauge, and can also lead to the destruction of individual components for more complex milled parts in order to reliably check certain quality factors. For example, it is more difficult to check whether the hardening of a milled part has been carried out correctly, as it may have to be destroyed for the test. If complex testing is necessary, this must also be taken into account in the number of components to be manufactured! However, it must also be said that quality controls are planned and carried out differently depending on the individual component and the company's requirements.

Before a component can be manufactured, it must first be planned and designed. Planning plays a central role in this process,

to reduce costs and avoid errors during production. For example,

the intended use of the component should be taken into account and design rules (material, wall thicknesses, tools, surface tolerances) should be applied. The choice of material for the finished component also plays an important role in the planning and production process. In order to save costs in production and avoid possible sources of error, drawings should always be checked (completeness, feasibility).

With the help of PART FACTORY, you only have to worry about the careful design and correct material selection of your desired milled part.

You can then submit your enquiries quickly and easily in the PART FACTORY portal. The manufacturers in PART FACTORY's certified network will provide you with a customised quote that you can order.

As the manufacturers produce milled parts on a daily basis, they know what is important when it comes to machining with the milling manufacturing process. This allows you to concentrate on your core business, design and material selection, while PART FACTORY takes care of the procurement of the milled part.

Test our service!

Convince yourself of our uncomplicated service and make a production enquiry. You will be surprised how little effort is required.

You can look forward to a high-quality prototype or a corresponding small series on the desired delivery date, which fully corresponds to your production drawing. Give it a try - it's worth it!

Post enquiry now

![[Translate to English:] PART FACTORY - Kontaktaufnahme [Translate to English:] PART FACTORY - Kontaktaufnahme](/fileadmin/_processed_/2/4/csm_woman-2773007__340_590260e0fe.jpg)