To manufacture CNC milled parts, you need highly functional CNC milling machines and well-trained specialists. Or you can have your CNC parts milled and rely on us as an experienced service provider.

Is contract manufacturing a strategic option for you? Would you like to make your company more agile, efficient and competitive?

Our high level of expertise in all aspects of the milling / CNC milling manufacturing process and our many years of experience as a CNC contract manufacturer will convince you. Order the required milled parts online and we will manufacture your parts at favourable conditions and in excellent quality. Guaranteed.

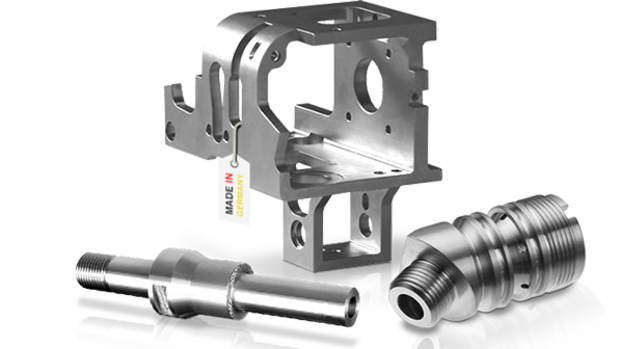

As a well-networked contract manufacturer, we operate on an international level. Our access to the best producers who mill CNC parts offers far-reaching advantages. If you have your CNC parts milled by PART FACTORY, you will receive perfect precision milled parts that meet your exact requirements with minimum effort.

It goes without saying that we are available for a wide range of orders and order volumes.

CNC milling machines have become an integral part of modern production. Thanks to the latest CNC technology and modern 5-axis machining centres, milling machines leave almost nothing to be desired. If you have your components CNC milled by us, anything is possible when it comes to shaping the workpieces.

Components with a wide variety of geometries and made from almost any material can be manufactured with high precision. PART FACTORY only uses modern CNC milling machines. All the components you require are produced to the highest quality. Convince yourself of our service now and submit a production enquiry!

- Thread milling is a process for creating precise threads on screws, bolts or other components.

- In 3-axis milling, the milling tool moves along the X, Y and Z axes.

- 5-axis milling enables the milling tool to move along five axes: X, Y, Z and two additional rotation axes, which enable complex machining operations.

- Surface milling produces a flat and smooth surface and is often used for finishing large surfaces.

- In profile milling, the milling tool is guided along a predefined contour and is well suited to the production of parts with complex contours and varying heights.

- Face milling refers to the milling of the face of a workpiece and is often used to produce flat surfaces.

- Roll milling is used to create specific grooves or profiles on the surface of the workpiece by rotating it in an axial direction.

- In circular milling, the milling tool moves along a circular path to create round shapes and cylindrical parts such as shafts or bolts.

- Functional milling combines various milling movements, to produce particularly complex parts.

- And much more: Do you have special requirements?

PART FACTORY offers the solution.

Milling is one of the most common machining processes, is widely used and has long been established in industry. In CNC milling, the workpiece is firmly clamped and can be approached by the milling tool in the X, Y and Z axes. The main cutting movement during milling is caused by the rotation of the tool. Milling, also known as CNC milling, is a subtractive manufacturing process, i.e. all the material that is not required for the finished workpiece is removed from the semi-finished product. 5-axis milling machines are used for very complex components. In addition to the three conventional axes, two further axes can be used, making "3D milling" possible. In addition to producing the inner and outer contours of the workpiece, CNC milling can also be used to produce threads. All of this is made possible by computer programmes that control the movements and actions of the milling machine. We always rely on well-trained experts who specialise in programming CNC machines. The best knowledge of CAD (Computer Aided Design) and CAM (Computer Aided Manufacturing) software is a matter of course when you commission CNC milling at PART FACTORY.

Milling machines are automated machining centres that produce with high precision. Accuracies of up to 0.001 mm and surface roughnesses of up to an average roughness depth of Rz 1.6 are possible.

Almost every common material can be CNC milled at PART FACTORY. In addition to the usual types of steel and aluminium, plastics are also available. Titanium, bronze, brass, precious metals and many other materials are just as suitable. Nevertheless, attention must be paid to the so-called machinability of the material. If a material that is difficult to machine is used, the price, delivery time and achievable accuracy often suffer.

We have already utilised our CNC milling services in a wide range of industries: Mechanical engineering, aerospace, automotive, medical technology and electronics manufacturing.

At PART FACTORY, we have many years of experience and extensive expertise in milling. We will be happy to advise you quickly and easily if you would like to order milled parts online.

If you have already exhausted your production capacities and are experiencing bottlenecks, contract manufacturing is ideal for you. With us at your side as a contract manufacturer, you can draw on the full potential. Of course, we don't just mill for you in the event of capacity bottlenecks, but are also happy to take over the production of your milled parts on a permanent basis.

Outsource your production and benefit from our expertise in metalworking.

Your advantages with PART FACTORY

- Customised production of milled and turned parts

- Elimination of a tedious search for suppliers

- You receive your quotation within 3 working days

- Submit a production enquiry quickly and easily - free of charge!

- Uncomplicated online processing from enquiry to delivery

- Professional production technology of the highest quality

As a B2B contract manufacturing portal, www.partfactory.com offers a high level of core expertise in the production of metal components.

We place production orders with a suitable manufacturer from our network of qualified contract manufacturers throughout Europe. These reliable partners then produce the ordered components exactly according to the given specifications.

We continuously check all manufacturers, their production processes and the manufactured parts. For example, we carry out spot checks to verify dimensional accuracy and tolerances, surface quality and the quality of the materials used. Careful documentation of all checks guarantees our high quality standard.

Customer data and communication flow exclusively between you and PART FACTORY.

This means that we take over several key elements of your procurement process and save you valuable resources such as time, money and personnel.

If you have any questions about our services, we look forward to hearing from you.

Commission our milling shop!

Request a quote for your milled parts online today and we will get to work for you straight away. Use our simple online form and put your trust in our experience.

You can calculate with confidence, receive your milled parts on the required date and easily meet your own delivery deadlines.

Create an enquiry now for small series, prototypes and we will mill for you.

Request CNC milled parts online

CNC milling is a versatile production technique. The range of materials we can process is large. Frequently processed materials include:

- Metals: aluminium, steel (stainless steel, carbon steel), copper, brass, titanium or alloys such as Inconel and Hastelloy

- Plastics: acrylic (PMMA), polycarbonate (PC), polyethylene (PE), polypropylene (PP), PVC (polyvinyl chloride), nylon and PEEK (polyether ether ketone)

- Composites: GRP (glass-fibre-reinforced plastic), CFRP (carbon-fibre-reinforced plastic), aramid-fibre composites (such as Kevlar)

- Foams: polyurethane foam, polystyrene foam (EPS), polyethylene foam

- Rubber: natural rubber, silicone rubber, ethylene propylene diene rubber (EPDM)

What types of CNC milling machines are available at PART FACTORY?

As a CNC contract manufacturer, PART FACTORY has an excellent producer network and can therefore access all kinds of CNC milling machines. Whatever you want to have CNC milled: We can offer fast and easy production with the perfect matching CNC milling machine. Whether 3-axis, 4-axis or 5-axis milling machines: From the comparatively simple workpiece to the particularly complex part, you will find the right offer with us.

CNC milling usually provides improved efficiency, accuracy and flexibility in manufacturing lead. If you have your milled parts manufactured online with us, you will benefit in particular from these advantages:

- Precision and repeatability: Once the specifications for the manufacture of your workpiece are stored in the system, computer-controlled precise manufacturing enables highly accurate and repeatable results. This is particularly important for demanding applications in industries such as aerospace, medical technology and mechanical engineering.

- Automation and productivity: CNC milling machines work efficiently and productively, reducing production times.

- Flexibility in production: In case of adjustments to your workpiece, our online portal for CNC contract manufacturing enables a quick and flexible changeover of production orders.

- Excellent surface quality: The CNC control enables precise control of the cutting speed and other machining parameters, resulting in improved surface quality of the machined parts.

![[Translate to English:] Ginko - Kunde bei PART FACTORY [Translate to English:] Ginko - Kunde bei PART FACTORY](/fileadmin/_processed_/b/3/csm_gingko_d8e1b124e8.png)

![[Translate to English:] EMEC - Kunde bei PART FACTORY [Translate to English:] EMEC - Kunde bei PART FACTORY](/fileadmin/_processed_/2/8/csm_emec_877abde238.png)

![[Translate to English:] Colandis - Kunde bei PART FACTORY [Translate to English:] Colandis - Kunde bei PART FACTORY](/fileadmin/_processed_/4/b/csm_colandis_873427207b.png)

![[Translate to English:] LSB Lift Service Bochum GmbH - Kunde bei PART FACTORY [Translate to English:] LSB Lift Service Bochum GmbH - Kunde bei PART FACTORY](/fileadmin/_processed_/9/8/csm_LSB_c75a04b96f.png)

![[Translate to English:] Digital Film Technology GmbH - Kunde bei PART FACTORY [Translate to English:] Digital Film Technology GmbH - Kunde bei PART FACTORY](/fileadmin/_processed_/6/c/csm_dft_517b9d750b.png)

![[Translate to English:] Frästeil von PART FACTORY [Translate to English:] Frästeil von PART FACTORY](/fileadmin/_processed_/d/c/csm_PARTFACTORY_Fraesteil_8_b1d5d34b2a.jpg)

![[Translate to English:] PART FACTORY - Ihr Experte für das Fräsen [Translate to English:] PART FACTORY - Ihr Experte für das Fräsen](/fileadmin/_processed_/f/0/csm_PARTFACTORY_Fraeskopf_c33c409031.jpg)

![[Translate to English:] E-Mail-Button PART FACTORY [Translate to English:] Service-Mail an PART FACTORY](/fileadmin/_processed_/2/8/csm_button-email_7338b53c45.png)

![[Translate to English:] Fräsen in der Lohnfertigung [Translate to English:] Fräsen in der Lohnfertigung](/fileadmin/_processed_/7/e/csm_Fotolia_84086353_XS_52c0aa1d1d.jpg)

![[Translate to English:] Fräsen als Lohnfertiger [Translate to English:] Fräsen als Lohnfertiger](/fileadmin/_processed_/f/a/csm_PARTFACTORY_Fraeskopf_silber_ac498e4f57.jpg)

![[Translate to English:] PART FACTORY - Testen Sie unseren Service [Translate to English:] PART FACTORY - Testen Sie unseren Service](/fileadmin/_processed_/5/1/csm_PARTFACTORY_Bauteil-in-einer-Hand_e0b1a8b59e.jpg)

![[Translate to English:] PART FACTORY - Kontaktaufnahme [Translate to English:] PART FACTORY - Kontaktaufnahme](/fileadmin/_processed_/d/9/csm_PARTFACTORY_Kontaktaufnahme_999b50609b.jpg)